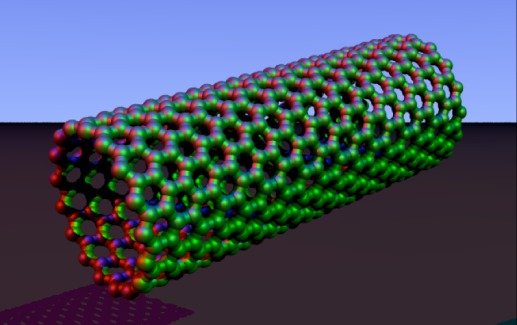

Carbon nanotubes (CNTs) have been regarded as one of the most exciting nanomaterials of the ages. They are flexible, strong, lightweight, fierce conductors of heat and electricity. Due to these special properties, they have found application in the aerospace, electronics, energy storage, and even the area of medicine.

CNTs are, however, seldom produced pure when produced. They may include metal catalysts, amorphous carbons, and indifferently unrelated to the manufacturing procedure. The impurities decrease the performance and restrict the applications of these. That is why, before the carbon nanotubes can perform remarkably, they require the most significant process, which is purification.

This article will tell you why purification is needed, will expound on the main ways of performing it, and will underline the necessity to collaborate with a trustworthy carbon nanotube manufacturer.

The necessity of Purification

CNTs are normally prepared as raw forms by such methods as laser ablation, arc discharge, and chemical vapor deposition (CVD). Although such ways are effective, they result in the discarding of unwanted materials, which include:

- Catalysts made of metals such as iron, cobalt, or nickel, Metal particles.

- The non-organized carbon that covers CNTs is called amorphous carbon.

- Oiling of carbon nanoparticles, which form mixtures with CNTs, lowers the quality.

If these impurities are not eliminated, CNTs can lose their conductivity, mechanical strength, or stability. In a case example, in medical applications, toxicity can be triggered by leftover metals. In the electrical field, impurities deteriorate the conductivity and reliability.

Therefore, the purification of carbon nanotubes guarantees that CNTs operate satisfactorily under advanced applications.

Purification methods

CNTs can be purified in a number of ways based on the amount of contaminants present and the application needed. The three most frequently occurring are:

1. Chemical Purification

- Chemical methods work by the use of acids or oxidizing agents to strip amorphous carbon and metals.

- Acid treatment: Aqueous solution of strong acids such as nitric acid (HNO 3 ) or hydrochloric acid (HCl) dissolves the metal particles.

- Oxidation: Amorphous carbon is burnt out by oxidizing agents with no harmful impact on CNTs.

Advantages:

- Works well to strip metals and excessive carbon

Disadvantages:

- CNTs can be shortened or damaged using any harsh chemicals.

- Should be handled with care to avoid the collapse of the structure

2. Physical Purification

- Size, shape, or density are used as the basis to separate the CNTs and impurities in physical methods.

- Filtration: CNTs, although captured, allow the passage of small particles; they are deposited on the filter.

- Centrifugation: Rotation at high velocity differentiates the CNTs in consideration of weight.

- Microscopy sorting: Sophisticated methods sort CNTs by using a microscope.

Advantages:

- No rough chemicals used

- Holds CNT structure with higher efficiency than the use of acid treatments

Disadvantages:

- Does not get rid of all impurities

- Effective with the subsequent application of chemicals

3. Thermal Purification

- The thermal method involves the removal of unwanted carbon or the dissolution of impurities through heat.

- Thermal oxidation: Under careful heat conditions, amorphous carbon is removed

- Vacuum annealing: CNT surfaces are cleaned during the heating in a vacuum and not damaged by oxygen.

Advantages:

- Effective in the removal of amorphous carbon

- Simple process

Disadvantages:

- The possibility of destroying CNTs if the case temperature is too high

- Metals can stay, provided there is no acid treatment used with them.

Combined Approaches

Frequently, it cannot be done with the help of one approach. This is the reason why the researchers employ such combinations as acid treatment + thermal oxidation or filtration + centrifugation. Such hybrid strategies have better purity and maintain the CNT structure.

In one example, a CNT batch can be acid-treated to remove metals and then heated in vacuo to remove any carbon impurities left behind.

The Process of a Standard CNT Purification

- Raw CNTs sample preparation: Take raw CNTs in the process.

- Acid treatment: Dissolve and extract catalyst metals.

- Heating or burning off (oxidation) amorphous carbon.

- Filtration or centrifuging-Isolate CNTs out of undesired byproducts.

- Drying and storage- Make purified CNTs ready.

The significance of a Quality Manufacturer

The required difficulty and economic challenge of purification reveal the reason to consider which carbon nanotube manufacturer to pick. Good quality, CNTs at production, need less cleaning and preserve the structure. A supplier with a history of good quality is also cost-effective in terms of time and risk to the industry that uses CNTs.

Conclusion

Carbon nanotubes stand to benefit from the full potential through their purification. Regardless of the method of removal, chemical, physical, or thermal, the removal of the impurities guarantees the realization of the outstanding features of strength, conductivity, and stability of the CNTs. In most instances, the best results are obtained by a combination of purification methods.

Industries can make CNTs fulfill stringent quality requirements by collaborating with a carbon nanotube manufacturer and by applying the appropriate purification strategy. Next-generation technologies in the fields of energy, medicine, and electronics rely on the purified CNTs.