Kalibraatio is one of the most critical processes across industries, from technology and manufacturing to science and healthcare. It ensures that measuring instruments function properly and deliver reliable results. In this comprehensive guide, we’ll explore what kalibraatio means, why it’s essential, and how it can be effectively implemented. This is your ultimate resource whether you’re a beginner or an industry expert.

What does kalibraatio mean?

Kalibraatio, or calibration in English, refers to the process of verifying the accuracy of a measuring device by comparing its results against a known standard. When discrepancies are identified, the device is adjusted to match the correct value. This process eliminates systematic errors and enhances measurement reliability.

For example, kalibraatio of a thermometer involves checking its readings against reference temperatures and adjusting it if it deviates from the actual temperature.

Why is kalibraatio important?

Kalibraatio is vital for several reasons:

- 🔥 Safety: Inaccurate measurements can cause dangerous situations in fields like medicine or aviation.

- 💰 Cost savings: Errors in measurement often lead to production waste and increased expenses.

- 📈 Quality assurance: Companies must comply with international standards, such as ISO 9001, which require regular kalibraatio.

By maintaining precise measurements, kalibraatio ensures efficient processes and products that meet quality standards.

Types of kalibraatio

Factory Calibration

Performed by the manufacturer before delivery, factory kalibraatio ensures that the device meets its technical specifications out of the box.

Field Calibration

Field kalibraatio is carried out on-site in the device’s actual working environment. This is crucial because environmental factors like temperature and humidity can affect measurement accuracy.

Post-use Calibration

Also called recalibration, this process involves testing devices that have been in operation for a certain period to detect wear-and-tear or environmental influences causing deviations.

The kalibraatio process: Step by step

The kalibraatio process generally involves five key stages:

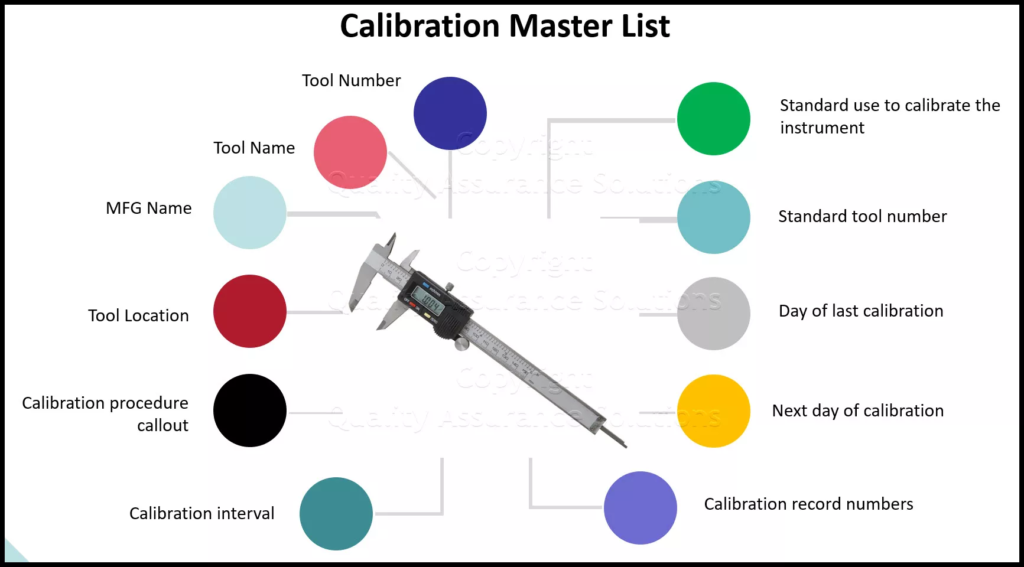

- Planning: Identify which devices require calibration and set intervals for recalibration.

- Comparison: Measure and compare device outputs to known standards.

- Adjustment: If deviations are found, fine-tune the device to align with the reference.

- Documentation: Record all actions and results in a calibration certificate.

- Monitoring: Schedule the next kalibraatio to maintain consistency.

This structured approach guarantees that the calibration meets technical and regulatory requirements.

International standards and certifications for kalibraatio

Many industries demand kalibraatio according to global standards:

- ISO/IEC 17025 – Competence of testing and calibration laboratories

- ISO 9001 – Quality management systems

- ANSI/NCSL Z540 – Calibration systems standard (USA)

Laboratories performing kalibraatio often require accreditation to these standards to ensure their results are officially recognized.

Common challenges in kalibraatio

Even though kalibraatio is critical, it’s not without challenges:

- ⏳ Downtime: Regular calibration may require taking devices offline, impacting operations.

- 💸 Costs: High-precision device calibration can be expensive.

- 🌡️ Environmental factors: Temperature, vibration, and humidity can affect calibration accuracy, especially in field conditions.

These challenges can be overcome with proper planning and reliable calibration service providers.

Benefits of kalibraatio for businesses

Consistent and professional kalibraatio provides numerous advantages:

✔️ Ensures product and service quality

✔️ Minimizes production waste and customer complaints

✔️ Strengthens customer trust and brand reputation

✔️ Helps comply with laws and industry regulations

Investing in kalibraatio pays off through improved efficiency and long-term savings.

Digital kalibraatio: A new era of accuracy

As technology advances, kalibraatio is also becoming more digital. Remote calibration, IoT-based monitoring systems, and AI-driven analytics are emerging as tools for real-time device calibration without physical intervention.

This minimizes downtime and boosts accuracy even further, opening doors for smart factories and automated quality control.

Summary

Kalibraatio is a fundamental process across industries where measurements affect safety, quality, and cost-efficiency. Regular calibration, adherence to international standards, and leveraging modern technologies ensure measuring instruments remain accurate and trustworthy.

For organizations, this means greater competitiveness, regulatory compliance, and stronger customer confidence. Whether it’s in a laboratory, on a production line, or in a hospital, kalibraatio is the invisible backbone supporting operational excellence.

FAQs – Frequently asked questions about kalibraatio

How often should kalibraatio be performed?

– Frequency depends on device type and usage but is commonly recommended at least once per year.

Can kalibraatio be done in-house?

– For some devices, yes. But official calibration often requires an accredited laboratory for certification.

What happens if kalibraatio is neglected?

– It can lead to inaccurate results, reduced quality, increased costs, and even legal penalties.

Read Also:- Yell51x-Ouz4