In the high-stakes world of medical device manufacturing, the margin for error is zero. A single defective component—a micro-crack in a catheter, a misassembled valve in a heart pump, or a contaminant on a surgical implant, or micro defects on an intraocular lens—can have dire consequences for patient safety and lead to catastrophic recalls for manufacturers.

This is where quality inspection transforms from a routine checkpoint into a critical, non-negotiable pillar of the production process. While human inspectors play a vital role, the complexity and miniaturization of modern medical devices demand a more precise, reliable, and data-driven approach: Automated Optical Inspection (AOI). And for the most complex parts, off-the-shelf AOI systems fall short, necessitating the development of sophisticated custom AOI solutions for complex shaped medical devices .

This article delves into the why, what, and how of using custom AOI to ensure the utmost quality and safety in medical device production.

The Unforgiving Demands of Medical Device Quality

Medical device inspection is governed by stringent regulations like FDA 21 CFR Part 820 in the U.S. and the ISO 13485 standard globally. These frameworks mandate a “quality first” approach, requiring manufacturers to have rigorous processes for verifying that every device meets its predefined specifications.

The challenges are multifaceted:

- Miniaturization: Devices like pacemakers, neurostimulators, and endoscopic tools contain components often measured in micrometers. Human vision cannot reliably inspect features at this scale for hours on end.

- Complex Geometries: Parts are no longer simple squares and circles. They include intricate 3D shapes, undercuts, internal channels (lumens), and transparent materials, all of which are difficult to illuminate and image consistently.

- Critical Tolerances: A misalignment of a few microns in a fluidic chip or a weld seam defect invisible to the naked eye can cause a device to fail.

- Material Variety: A single assembly may combine metals, polymers, silicones, and glass, each with different reflective and refractive properties, complicating the imaging process.

- 100% Inspection Requirement: For many critical components, sampling is not enough. Every single part must be inspected to guarantee safety.

What is Automated Optical Inspection (AOI)?

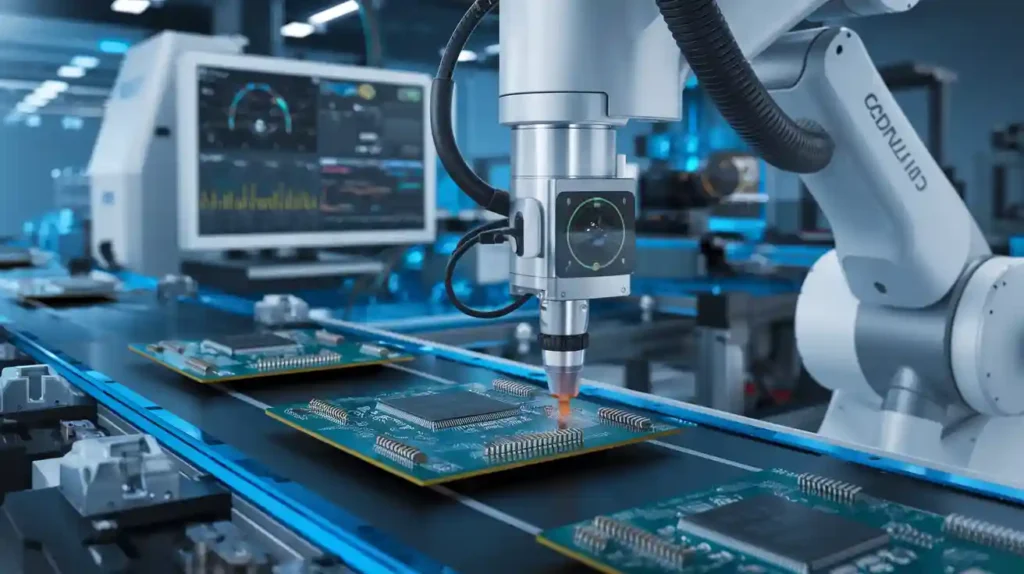

At its core, AOI is a technology that uses cameras, lighting, and software to automatically compare a manufactured part to a digital “golden standard” or a set of programmed acceptance criteria.

A basic AOI system performs:

- Dimensional Measurement: Checking lengths, diameters, and angles.

- Presence/Absence Verification: Confirming all components are placed.

- Surface Defect Detection: Identifying scratches, voids, discoloration, or contamination.

- Positional Accuracy: Verifying the correct placement and orientation of features.

When Off-the-Shelf AOI Isn’t Enough: The Case for Custom Solutions

Standard AOI systems are excellent for printed circuit board (PCB) inspection or checking simple mechanical parts. However, complex medical devices present unique challenges that require a tailored approach. Here’s why custom AOI is essential:

1. Unique and Complex Part Features:

- Example: Injectable Drug Delivery Pens. Inspecting the internal thread engagement, needle shield presence, and dosage dial alignment requires a specific camera angle, lighting setup, and motion control that a standard system cannot provide.

- Custom Solution: A system would be engineered with multiple high-resolution cameras (top, side, oblique) and specialized lighting (e.g., coaxial, dome) to eliminate glare and highlight the critical internal and external features simultaneously.

2. Challenging Materials and Surfaces:

- Example: Transparent Syringe Barrels. Inspecting for glass particulates, bubbles, or cosmetic defects in a clear cylinder is extremely difficult. Standard lighting creates reflections and hotspots that obscure defects.

- Custom Solution: A system might use darkfield illumination to make particulates and scratches scatter light and appear bright against a dark background. Advanced image processing algorithms would be trained to differentiate between acceptable bubbles and unacceptable contaminants.

3. 3D and Volumetric Inspection:

- Example: Orthopedic Implants (e.g., knee joints). These parts have complex 3D curves and porous surfaces that must be free of burrs and have specific surface roughness. A 2D camera cannot assess this.

- Custom Solution: Integration of 3D profiling technologies like laser triangulation or structured light scanning. A laser line is projected onto the part, and a camera captures the deformation of that line to build a precise height map, allowing the software to measure volume, depth, and surface topography.

4. In-process and Assembly Verification:

- Example: Automated Assembly of Surgical Staplers. The inspection needs to happen during the assembly process to provide immediate feedback and prevent a whole batch from being misassembled.

- Custom Solution: A custom AOI station is integrated directly into the robotic assembly cell. It performs a check after each robotic operation (e.g., “Was the spring placed correctly?”). If a fault is detected, it signals the robot to stop or correct the process, enabling closed-loop process control.

The Anatomy of a Custom AOI Solution

Building a custom AOI system is a multidisciplinary effort involving optical engineering, mechanical design, and software development.

- Precision Imaging System:

- Cameras: Selection of resolution (2MP to 25MP+), sensor type (CMOS/CCD), and frame rate based on the required detail and throughput.

- Lenses: Macro lenses for extreme close-ups, telecentric lenses for distortion-free measurement, or special optics for imaging inside small holes.

- Lighting: The most critical element. Options include:

- Dome Lights: For diffused, reflection-free illumination of complex shiny surfaces.

- Darkfield Lights: To highlight surface irregularities and scratches.

- Backlights: For creating high-contrast silhouettes for dimensional measurement.

- Structured Light: For projecting patterns to enable 3D reconstruction.

- Robotic Handling and Motion:

- Precision stages to move the part or the camera with micrometer accuracy.

- Robots or actuators to present the part in specific orientations for multi-angle inspection.

- The Brain: Sophisticated Software & Algorithms

- Traditional Rule-Based Algorithms: Use tools like edge detection, blob analysis, and pattern matching. They are powerful for well-defined, predictable features. (“Find this edge and measure its position.”)

- Artificial Intelligence (AI) and Deep Learning: This is a game-changer for custom AOI.

- How it works: Instead of programming specific rules, the system is “trained” using thousands of images of both “good” and “bad” parts.

- Why it’s perfect for medical devices: It excels at identifying defects that are difficult to describe with rules, such as subtle cosmetic variations, acceptable biological residue on a donated tissue graft, or classifying complex assembly states. It adapts to natural variations in appearance.

- Integration and Data Management:

- The system must seamlessly integrate with factory automation (PLCs, robots).

- It must collect, analyze, and store inspection data to provide traceability and support regulatory compliance (e.g., creating audit trails per FDA requirements).

Benefits Beyond Defect Detection: The ROI of Custom AOI

Investing in a custom solution offers profound returns:

- Unmatched Quality and Patient Safety: The primary goal—catching defects no human or standard system could find.

- Massive Data Collection: Enables statistical process control (SPC), identifying trends and potential process drifts before they create rejects.

- Increased Throughput and Efficiency: Inspection happens in seconds, far faster than human operators, without fatigue.

- Reduced Cost of Quality: Catches defects early, preventing costly rework or scrap of fully assembled devices and mitigating the enormous risk of a recall.

As medical devices continue to become more complex and life-critical, the methods for ensuring their quality must evolve in parallel. Custom Automated Optical Inspection is no longer a luxury but a necessity for leading manufacturers. By combining precise optical systems, robotic handling, and powerful AI-driven software, custom AOI provides the unparalleled accuracy, repeatability, and traceability required to protect patients and uphold the highest standards of quality in the medical industry. It is the technological sentinel ensuring that every device that leaves the production line is truly safe and effective.