For every electronics product, from a simple IoT sensor to an advanced medical device, the performance starts with the quality of the assembly. That’s where a reliable PCBA service and supplier come into play.

If you want to reduce risks, speed up production, and ensure consistent product quality, working with the right PCBA supplier is not just a choice—it’s a necessity.

What Is a PCBA Service?

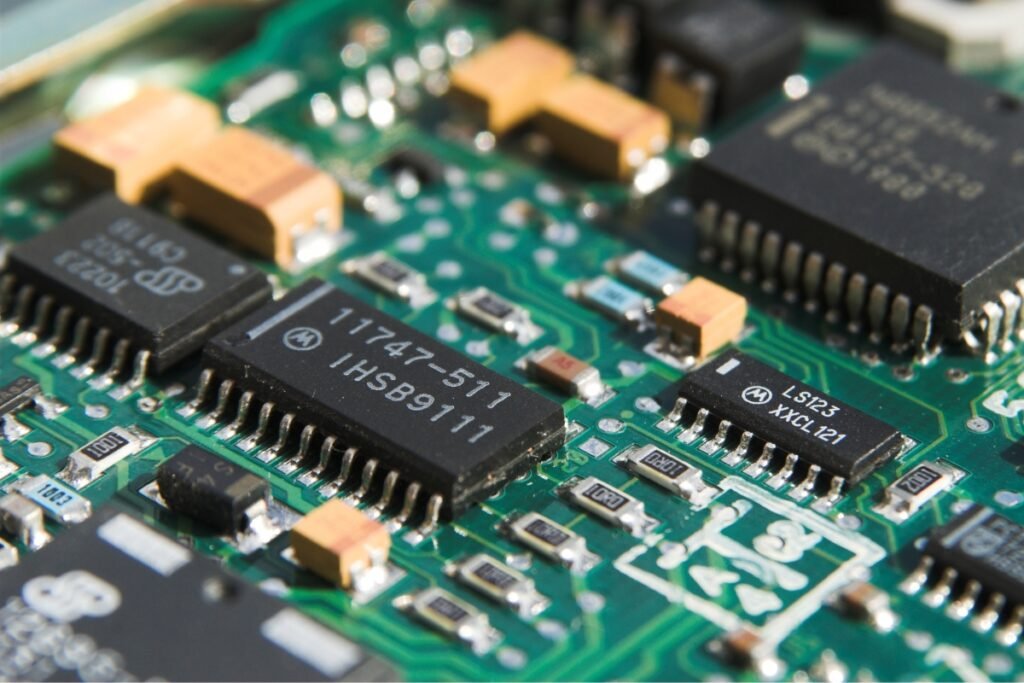

A PCBA (Printed Circuit Board Assembly) service is the process of assembling all electronic components onto a bare PCB. This involves:

- Preparing and reviewing the Bill of Materials (BOM)

- Procuring genuine components

- Surface Mount Technology (SMT) and/or Through-Hole Technology (THT) assembly

- Reflow or wave soldering

- Quality inspections (AOI, X-ray, visual check)

- Functional Testing (FCT)

Some advanced PCBA services also offer conformal coating, burn-in testing, and box build assembly as part of their turnkey solutions.

What to Expect From a Qualified PCBA Supplier

Not every PCBA supplier is capable of handling high-reliability or volume-sensitive projects. Here are some qualities that define a good PCBA supplier:

- In-house SMT lines with high-speed placement machines

- Proper ESD protection and cleanroom management

- Strong supplier network for sourcing components

- Capability to handle complex boards (multi-layer, fine pitch, BGA, etc.)

- Real-time communication and progress tracking

- Support for prototypes, small batches, and mass production

- Long-term stability, financial health, and factory certifications

Why Your Choice of PCBA Supplier Matters

A poor PCBA supplier can introduce issues like soldering defects, delayed shipments, BOM mismatches, or even component counterfeiting. These problems can derail your project and cost more than expected.

On the other hand, a reliable PCBA service provider ensures:

- Shorter lead times

- Stable quality across batches

- Clear project documentation

- Fewer revisions or rework

- Greater confidence when going to market

Your reputation depends on product performance—and that performance depends on the board assembly.

PCBasic: Your Partner for High-Quality PCBA Service

PCBasic is a professional PCBA supplier with over a decade of experience in delivering complete electronic manufacturing solutions. Located in Shenzhen, China, our team specializes in:

- Quick-turn PCBA for prototypes and pilot runs

- Industrial-grade PCB assemblies with strict IPC-A-610 standards

- End-to-end support from PCB fabrication to functional testing

- Serving industries such as telecom, smart home, medical, automotive, and IoT

We’re not just an assembly house—we’re a collaborative partner who cares about your product success.

Things to Check Before Finalizing a PCBA Supplier

Before you lock in a PCBA service provider, verify the following:

- Do they review your Gerber files and BOM before production?

- Are their certifications and quality systems up to date?

- Can they handle component shortages and suggest alternatives?

- Are their test and inspection capabilities suitable for your requirements?

- Can they scale with your business?

Choosing a trustworthy PCBA supplier early in your product life cycle saves you headaches later.

Looking for a proven PCBA supplier to support your next electronics build? Reach out to PCBasic and see how our fast, flexible, and reliable PCBA service can help your business grow.