Vibrations are present in many products. All vehicles, telephones, equipment, and tools tremble. The movement caused by the vibration may break components or slip fittings. Companies test products using vibration equipment for this reason. The testing demonstrates the strength and dependability of a product.

What are the Vibration Testing Machines?

Test equipment in which vibration is controlled is called vibration testing equipment. It examines how products respond to these forces. The machinery is numerous. Both parts have distinct jobs. The combination of them generates, quantifies, and regulates vibrations.

The Vibration Test Equipment Main Components

These are the main parts:

- Shaker table

- Power amplifier

- Control system

- Accelerometer or sensor

Both of them contribute to the safe and accurate testing of products.

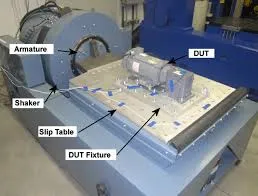

The Mechanics of The Shaker Table

The principal unit is the shaker table. It strikes vibrations in various ways. It is hydraulic or electric coiled. The table appears horizontally and vertically. This movement formulates vibration forces. The one that is tested is held fixed on the table. The table is moving, and the product is shaking with it.

The Power Amplifier’s Role

The shaker table is driven by the power amplifier. It conveys powerful electric messages. These messages generate fields of magnetism. The table coil is moved by a magnetic field. The more the power, the greater the vibrations. The amplifier makes sure that the correct force is applied to the product using the shaker.

Function of Control Systems

The vibration test is controlled by the control system. It controls the type of vibration, frequency, and intensity. Software is used to establish test patterns by engineers. The system maintains vibrations in a steady condition. It also gathers testing information. This information indicates the reaction of the product to be tested.

Sensors And Measures

The vibration on the product is determined using sensors. They are usually accelerometers. They feel the movement and the force upon the part. The information is transferred to the control system. It tells whether the vibration is on the mark. It also notes product reactions. This data is used to analyse results by engineers. Digital Low-Frequency Vibration Testing Machine controls electromagnetic vibration and thus is very efficient machinery.

Vibration Testing Types

Testing is very numerous. This is a list of easy things:

- Random vibration tests

- Shock testing

- Resonance search and dwell

This makes use of one frequency at a time. It monitors product response at such a frequency.

Random Vibration Testing

It utilizes a lot of frequencies simultaneously. It has real-life vibration simulations. Transport and aerospace common tests.

Shock Testing

This employs abrupt, powerful forces. It goes on to determine whether products endure falls or knocks.

Resonance Search And Dwell

This locates the natural frequency of the product. It does this by measuring how the product responds in vibrations with that frequency.

The Functioning of A Digital Low-Frequency Vibration Testing Machine

Digital Low-Frequency Vibration Testing Machine is used in many companies. It generates low-pitched vibrations. These are the machines that test the products to be transported on the roads in terms of vibrations. Digital controllers are applied to make precise settings. The hydraulic or mechanical systems are used in low-frequency machines. They generate powerful, though deliberate, vibrations. It is handy in tests of auto parts and large-sized equipment.

Process In Vibration Testing

So here is an easy listed numbered list of the steps:

1. Mount the product on the hacker table

2. Connect sensors with the product

3. Establish control system patterns for set tests

4. Initiate vibration test

5. Monitoring of data during the test

6. At the end of the test, stop it

7. Check product performance by analysing data

Each step is of significance. It ensures the product is tested with safety and accuracy.

Applications Of Vibration Testing Machinery

Vibration Testing Equipment finds application in a wide variety of areas:

- Automotive industry

- Aerospace testing

- Electronics manufacturing

- Testing defence equipment

- Advancement of construction equipment

Such industries require powerful products. Vibrations provide weak points before product placement into the marketplace.

Advantages Of Vibration Analyses

The key advantages are the following:

- Enhances product quality

- Identifies defects in design at an early stage

- Avoids repair expenses in the future

- Makes it safe to use by the users

- Establishes faith with customers

The investment in quality and brand value is testing.

Conclusion

A safe product requires vibration testing. The Vibration Testing Equipment applies controlled vibrations to test parts. Digital Low-Frequency Vibration Testing Machine can be used on large and heavy parts. It makes high-intensity low-frequency vibrations to replicate the real usage. Testing proves that products are able to endure by being in real-life experiments. It ensures the safety of the users and trust in the brand. One should always use quality testing equipment in projects. It makes your products powerful to face the world.