In the ever-growing agricultural industry, efficiency and sustainability are not just goals—they’re necessities. One of the keys to achieving this balance lies in the smart design of your fertilizer plant. Whether you’re building a facility from the ground up or upgrading an existing one, your production line setup determines your output, product quality, and profitability.

Today, we’ll break down the essentials of designing a high-yield fertilizer plant, focusing on NPK fertilizer production lines, and how top-tier manufacturers like Cementl are helping businesses scale smarter, not harder.

What Is a Fertilizer Plant?

A fertilizer plant is a specialized industrial facility designed to manufacture various types of fertilizers, including NPK compound fertilizers (which contain nitrogen, phosphorus, and potassium). These facilities convert raw materials like urea, ammonium phosphate, and potassium chloride into nutrient-rich products used to boost soil fertility and crop yield.

Depending on the production method—granular, liquid, or powder—each fertilizer plant will have a customized setup. However, the most common and efficient system in modern agriculture is the NPK fertilizer production line.

Understanding the NPK Fertilizer Production Line

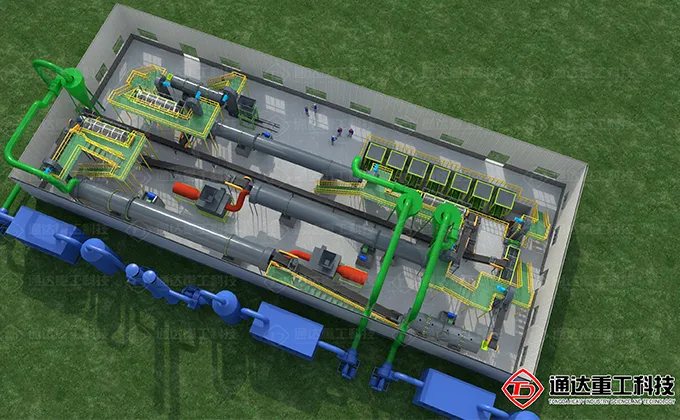

The NPK fertilizer production line is the heart of any high-yield fertilizer operation. It is designed to process raw nutrients into well-balanced, granulated fertilizers that are easy to store, transport, and apply. The typical production flow includes:

1. Batching System

Precise raw material measurement is crucial for consistent nutrient content. Automated batching units ensure each batch meets formulation standards.

2. Mixing Equipment

High-efficiency mixers blend nitrogen, phosphorus, and potassium sources uniformly, ensuring balanced nutrient distribution in every pellet.

3. Granulator

This is where the powder blend becomes granulated. Rotary drum granulators are commonly used for high-capacity production lines.

4. Drying and Cooling System

Newly formed granules are dried to remove moisture and cooled for stability. Efficient drying also helps prevent clumping and degradation during storage.

5. Screening and Coating

Oversized or undersized granules are separated, while coatings may be applied for moisture resistance or slow-release formulations.

6. Packaging Unit

Finally, the granulated NPK fertilizer is bagged, sealed, and labeled for distribution.

Key Factors in Designing a High-Yield Fertilizer Plant

Creating a fertilizer plant that consistently delivers high output starts with good design. Here are the top elements to focus on:

Layout Optimization

Your facility’s layout should minimize material handling time and energy consumption. Strategic placement of equipment can increase throughput and reduce labor needs.

Automation & Control Systems

Modern control systems allow for real-time monitoring of moisture content, temperature, and granule size, critical for quality control. Automation reduces errors, boosts safety, and enhances operational efficiency.

Equipment Quality

Investing in high-grade machinery ensures fewer breakdowns, better energy efficiency, and consistent product quality. This is where Cementl excels.

Cementl: Reliable Equipment for Fertilizer Plant Optimization

When selecting partners for your fertilizer plant’s setup or upgrade, the brand behind the equipment matters. Cementl, an industry leader with decades of experience in material processing and chemical manufacturing, provides a full suite of machinery for NPK fertilizer production lines.

Why Choose Cementl?

- Complete Line Solutions: From batching to granulation and packaging, Cementl offers integrated systems designed for scalability and performance.

- Durability & Efficiency: Built with top-tier materials, Cementl machinery is known for longevity and low maintenance costs.

- Eco-Friendly Design: Their energy-efficient dryers and dust-reduction technologies support sustainable production.

- Tailored Consultation: Whether you’re a start-up fertilizer plant or an established brand, Cementl customizes solutions to your production goals and regional compliance needs.

With Cementl, you’re not just buying machines—you’re investing in long-term productivity, quality assurance, and environmental responsibility.

The Bottom Line: Performance Starts at the Design Table

Whether you’re entering the fertilizer industry or scaling an existing facility, designing a fertilizer plant for high-yield production requires the right strategy, the best technology, and a forward-thinking partner like Cementl.

From selecting the most efficient NPK fertilizer production line setup to optimizing each stage for maximum output and minimum waste, smart design leads to better performance and greater profitability.

As the world demands more from agriculture, now is the time to ensure your fertilizer plant is built to deliver—today, tomorrow, and for years to come.