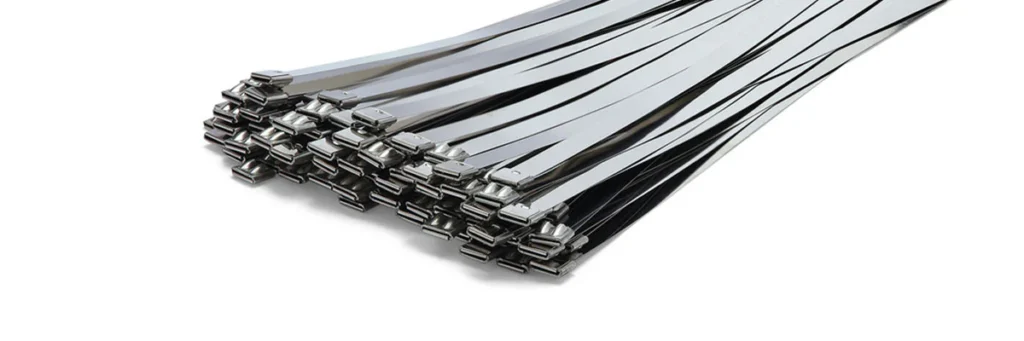

In industries where performance is critical, especially when dealing with high-pressure environments or heavy-duty applications, cable management is not something that can be taken lightly. Industrial operations that involve offshore rigs, power plants, high-temperature machinery, or environments with constant vibration rely heavily on durable and long-lasting solutions. Cable ties are an essential part of securing critical wiring systems, and when it comes to tough, demanding situations, SS cable ties are the go-to option.

Heavy-duty applications don’t forgive weaknesses. Even a minor failure can result in costly downtime, safety hazards, and significant operational losses. That’s why industries such as power generation, automotive manufacturing, marine, and chemical processing turn to stainless steel cable ties as their preferred solution for cable management in harsh environments. These ties stand out for their strength, heat resistance, and long-term dependability.

In this article, we will delve into why stainless steel cable ties are a reliable choice for these challenging environments, providing the performance and durability that industries need.

What Makes Stainless Steel Cable Ties Ideal for Tough Jobs

In most industrial environments, traditional plastic or nylon cable ties may suffice for routine tasks. However, in high-stress, high-temperature, or corrosive environments, plastic ties quickly fall short. They may be fine for general, low-demand uses, but when cables are exposed to heavy loads, fluctuating temperatures, or corrosive materials, these ties may weaken and fail. Stainless steel ties, on the other hand, are specifically designed to perform reliably under extreme conditions. Their advanced material properties make them the preferred choice for heavy-duty applications.

Unmatched Strength

One of the core benefits of stainless steel cable ties is their exceptional tensile strength. Designed to handle high tension without stretching or snapping, stainless steel cable ties can securely hold thick, bundled cables, power lines, and other vital wiring systems in place. This makes them an excellent choice for industries where cables are subjected to heavy mechanical loads, such as power plants, oil rigs, and manufacturing plants.

In environments where cables are under constant strain or subjected to movement, even slight stretches or bends can compromise the performance of traditional plastic ties. Stainless steel ties, however, maintain their strength and shape, ensuring that cables stay securely in place, preventing costly cable failures, and maintaining the integrity of critical electrical systems.

Fire and Heat Resistance

Another key advantage of stainless steel cable ties is their heat resistance. Industries such as thermal power plants, oil refineries, and automotive manufacturing often involve high-temperature environments where plastic cable ties cannot withstand prolonged exposure to extreme heat. As the temperature rises, plastic ties can soften, melt, or even burn, causing them to fail. Stainless steel ties, however, can withstand much higher temperatures, making them ideal for environments where temperatures regularly exceed what plastic ties can endure.

Whether securing cables near boilers, furnaces, turbines, or engine compartments, stainless steel ties maintain their strength and performance. Unlike plastic alternatives, which may degrade over time and compromise safety, stainless steel ties will continue to securely hold cables in place under high heat without compromising their structural integrity. This makes them an essential tool in high-heat environments where failure is simply not an option.

Corrosion Resistance

In many heavy-duty applications, cables are exposed to a variety of corrosive elements. Whether it’s saltwater, chemicals, oils, or gases, stainless steel cable ties excel in environments where corrosion is a constant threat. For example, in industries like marine operations, offshore oil rigs, and chemical processing plants, exposure to corrosive elements is a constant challenge. Traditional plastic ties cannot withstand the corrosive effects of salt, UV rays, or harsh chemicals and will quickly deteriorate over time.

Stainless steel cable ties are highly resistant to rust, salt spray, and chemical exposure. This corrosion resistance ensures that they will maintain their integrity and continue to perform effectively over the long term, even in the most corrosive environments. As a result, industries such as chemical processing, marine shipping, and oil and gas rely on stainless steel cable ties to secure their critical systems.

Vibration Tolerance

In environments with high levels of mechanical vibration, such as automotive assembly lines or industrial manufacturing plants, plastic cable ties often struggle to maintain a secure grip. Over time, these ties may loosen or fail altogether due to constant movement. Stainless steel cable ties, on the other hand, are incredibly vibration-resistant. Their robust construction ensures that they stay securely fastened even in settings where equipment is running continuously and vibrating at high intensity.

For example, engine compartments in automobiles and aerospace systems, where high-speed motion and vibration are common, require a cable management solution that can withstand these harsh conditions. Stainless steel ties hold cables securely in place, preventing any potential hazards that could arise from loosening cables, such as electrical shorts, fires, or equipment failure.

Where Stainless Steel Cable Ties Excel: Real-World Use Cases

The benefits of stainless steel cable ties shine brightest in industries and applications where failure could lead to downtime, safety hazards, regulatory fines, or catastrophic equipment failure. These are industries that require the ultimate in reliability and durability to keep operations running smoothly.

Automotive Assembly Lines

In the automotive industry, stainless steel cable ties are commonly used to secure cables and wiring systems in engine compartments, undercarriages, and braking systems. Exposure to high levels of heat, vibration, and oil requires a cable tie that can stand the test of time. Stainless steel ties ensure that cables stay securely fastened despite the extreme conditions found in automotive assembly lines, reducing the risk of failures that could disrupt production or compromise vehicle safety.

Thermal Plants

Thermal power plants rely heavily on cables to carry power and control signals to turbines, boilers, heat exchangers, and other critical equipment. In these environments, high temperatures and exposure to steam or hot gases can cause traditional cable ties to degrade rapidly. Stainless steel ties, with their heat resistance and long-lasting durability, ensure that cables are securely fastened even in these high-temperature environments, preventing failures that could lead to power loss or plant shutdowns.

Chemical Processing Units

Chemical processing facilities often expose cables to aggressive chemicals, acids, and caustic vapors. In these conditions, plastic cable ties will quickly deteriorate and fail. Stainless steel ties, however, provide excellent resistance to chemicals and harsh environments, making them the preferred choice for securing cables in chemical plants. Their resistance to corrosion, combined with their durability, makes them essential in ensuring the continuous operation of chemical manufacturing processes.

Marine & Offshore Platforms

Marine and offshore oil rigs face unique challenges with saltwater exposure, high winds, mechanical movement, and extreme weather conditions. In these environments, stainless steel cable ties are crucial for keeping cables and wiring systems secure. Saltwater, in particular, can quickly degrade other materials, making stainless steel ties the only viable option for securing cables on ships, platforms, and docks. These ties perform reliably, ensuring the safety of the rig, preventing electrical failures, and reducing the risk of costly maintenance.

Industrial Manufacturing

In industrial manufacturing plants, where heavy machinery, robotic systems, and electrical panels are common, stainless steel cable ties ensure that wiring systems remain securely fastened in even the most demanding environments. Constant vibrations, heavy equipment movement, and exposure to various environmental factors require a durable, high-performance cable tie that can stand up to these conditions. Stainless steel ties help maintain the integrity of wiring systems, ensuring equipment operates efficiently and safely.

Installation Tips for Maximum Lifespan

To ensure that stainless steel cable ties continue to perform at their best, proper installation is key. Here are some installation tips that can extend the lifespan of your cable ties and ensure maximum performance:

- Use Appropriate Tensioning and Cutting Tools: Proper tensioning ensures that the cable tie is secure without over-tightening, which could damage the cables or the tie itself.

- Avoid Over-Tightening: Over-tightening can cause coated ties to damage the underlying cables. Ensure you adjust the tie tightly enough to secure the cables but not too tight that it causes damage.

- Group Cables Based on Load and Temperature Exposure: For optimal performance, group cables based on their load and exposure to heat. This will prevent material stress over time, which could lead to premature failure.

- Maintain Consistent Installation Practices: Consistent and careful installation practices ensure that cable ties perform reliably and last as long as possible in tough environments.

Final Thoughts: Reliability That Pays Off

The choice of cable tie may seem like a small decision, but in heavy-duty industries, it directly impacts uptime, safety, compliance, and operational efficiency. Stainless steel cable ties provide the strength, heat resistance, corrosion protection, and vibration tolerance that demanding environments require.

Whether you’re securing cables in automotive systems, chemical processing, marine environments, or thermal plants, stainless steel ties are the reliable solution for heavy-duty applications. Their long-term durability and performance make them a wise investment that delivers long-term value.

By choosing stainless steel cable ties for heavy-duty applications, industries can minimize risks, ensure compliance with safety regulations, and maintain a steady and safe operation without the worry of frequent failures. In environments where every detail counts, the reliability of stainless steel cable ties can make all the difference.